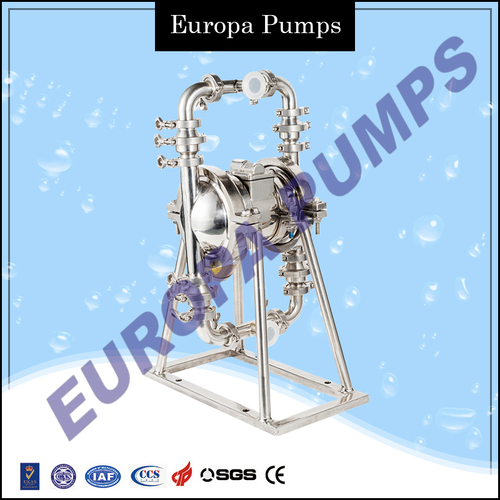

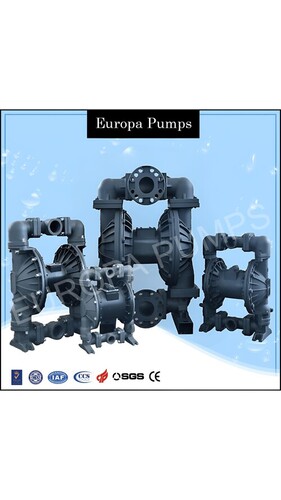

Hygenic Aodd Pump

Product Details:

- Size Various available

- Usage Industrial

- Color Silver

- Material Metal

- Pressure High Pressure

- Click to View more

Hygenic Aodd Pump Price And Quantity

- 1 Piece

- 500000 INR/Unit

Hygenic Aodd Pump Product Specifications

- Various available

- Industrial

- Metal

- High Pressure

- Silver

Hygenic Aodd Pump Trade Information

- 100 Piece Per Month

- 7 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

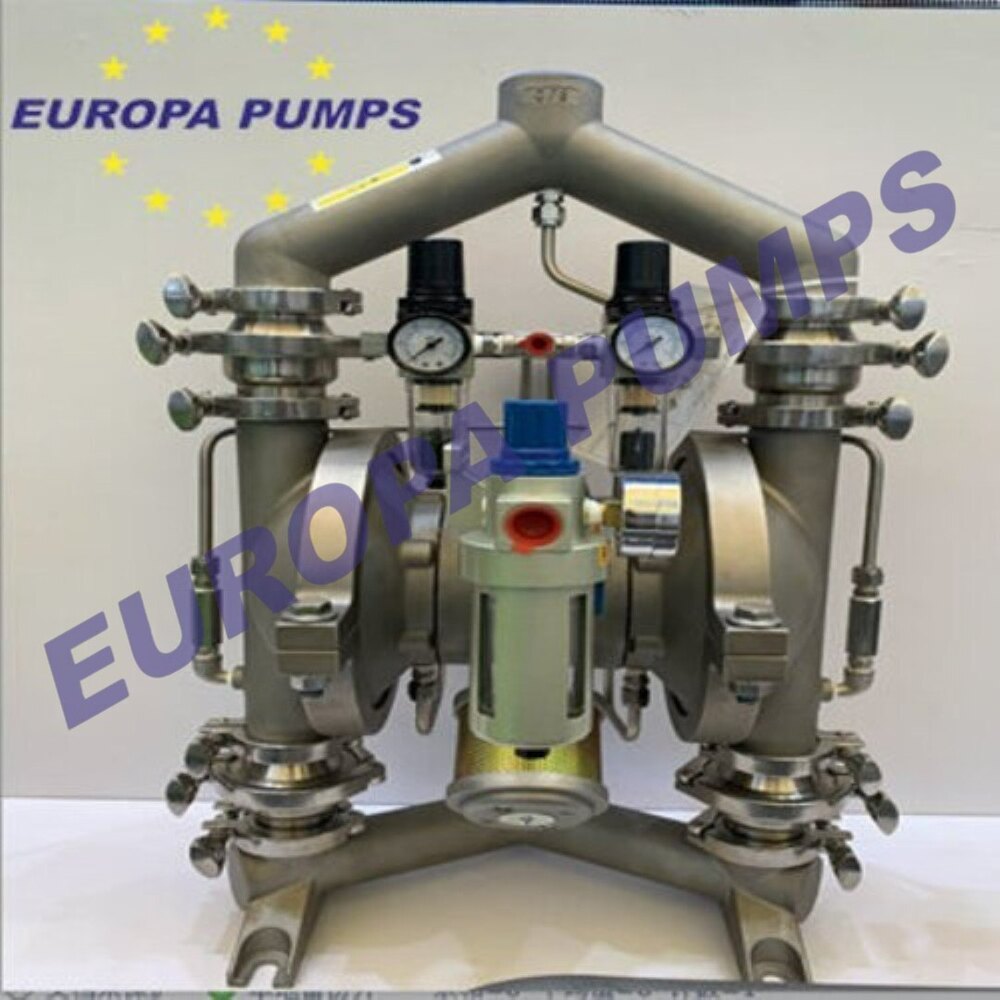

Engineered for the highest hygiene and safety standards, our Industrial Sanitary AODD Pumps are ideal for applications where cleanliness is critical, such as food and beverage processing and pharmaceuticals. Designed for easy cleaning and sterilization, these pumps feature advanced CIP (Clean-In-Place) capabilities, minimizing downtime and eliminating the need for disassembly during maintenance.

Constructed from high-grade stainless steel, they offer exceptional durability and corrosion resistance, making them robust enough for the harshest industrial environments. Their sealed seals ensure leak-proof operation, safeguarding product integrity and compliance with stringent hygiene regulations.

Powered by compress air, these pumps deliver reliable performance across various applications and are available in sizes ranging from 1 inch to 3 inches, allowing for versatile flow management. With a sleek silver finish that enhances any industrial setting, our Industrial Sanitary AODD Pumps combine high performance with ease of maintenance for a dependable solution in demanding environments.

FAQs of Hygienic AODD Pump

Q. What is a Hygienic AODD Pump?

A.  Hygienic Air-Operated Double-Diaphragm (AODD) Pump is designed for applications requiring high hygiene standards, such as in the food, beverage, pharmaceutical, and chemical industries. It operates using compressed air to move fluids through two diaphragms, ensuring that the pump components do not come into direct contact with the fluid. This design helps maintain cleanliness and prevents contamination, making it ideal for sensitive applications.

Q. Industries Using Hygienic AODD Pumps.

A. Food and Beverage: Transferring and processing edible products:-

-> Pharmaceutical: Handling sensitive and sterile formulations.

->Cosmetics: Moving creams, lotions, and personal care products.

->Chemical: Managing chemicals and additives with strict hygiene requirements.

Q. Is technical support available for troubleshooting and maintenance?Â

A. Yes, technical support is available to assist with troubleshooting and maintenance. You can reach out to customer service via phone, email, or through the website for assistance.Â

Q. How do the pumps ensure cleanliness?

A. The design allows for easy cleaning and sterilization, reducing downtime and maintaining sanitary conditions without needing disassembly.

Send Inquiry

Send Inquiry Call Me Free

Call Me Free